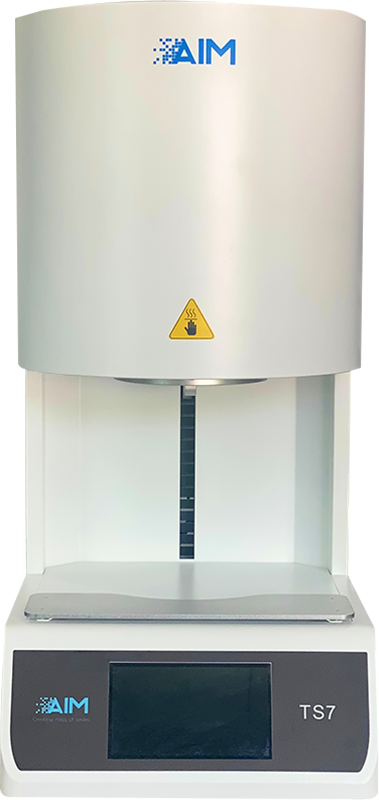

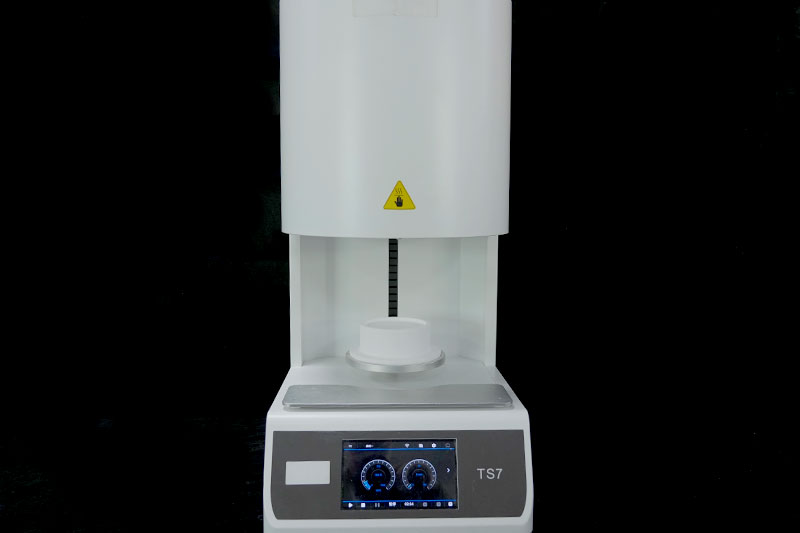

AIM-TS7 zirconia sintering furnace

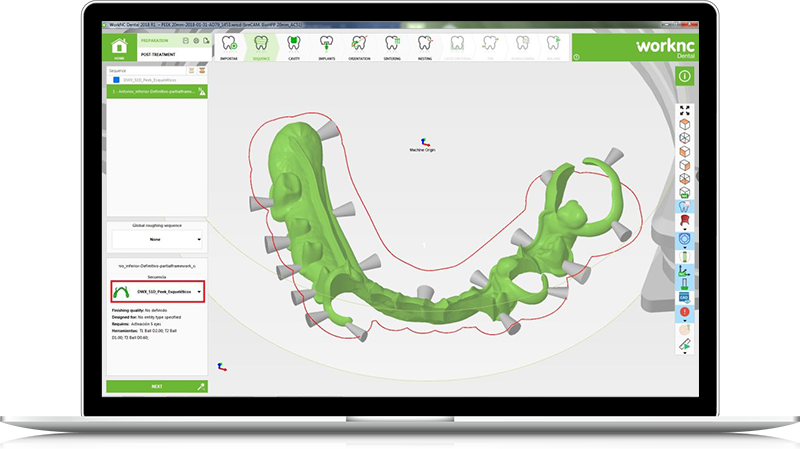

With Worknc、millbox、hyperdent CAM software and timely online technical support,there is no need to worry about grinding strategies

AIM-TS7 zirconia sintering furnace

Name

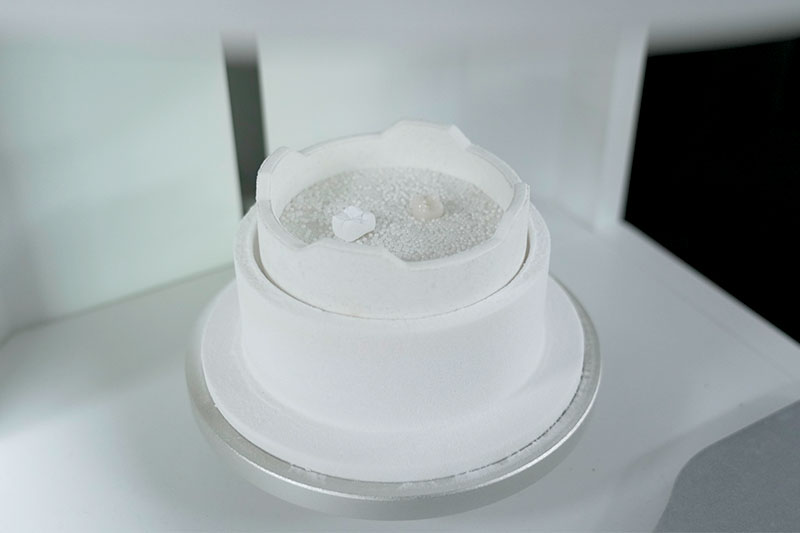

100×120 mm 70×80 mm

Heating zone

Intelligent PID multi-phase programmed temperature control

Control mode

±1 ℃

Temperature control precision

20 curves, multiple time-temperature curves can be set at will

Temperature curve

Digital display

Current/Voltage monitoring

Yes

Over temperature alarm

>30 kg

Weight

Type B thermocouple

Temperature measuring element

220V 50Hz~60Hz 1.5KW 2.5KW

Power supply

Lift type

Furnace chamber mode

Android + Intelligent PID control system

Control instrument

Imported fiber

Furnace chamber material

1600 ℃ (Mitsubishi)

Extreme temperature

≤1550 ℃

Operating temperature

≤60 ℃(recommended: 10 ℃/min)

Heating rate

Single temperature zone

Heating temperature zone

377×1500 mm

Furnace tube dimension