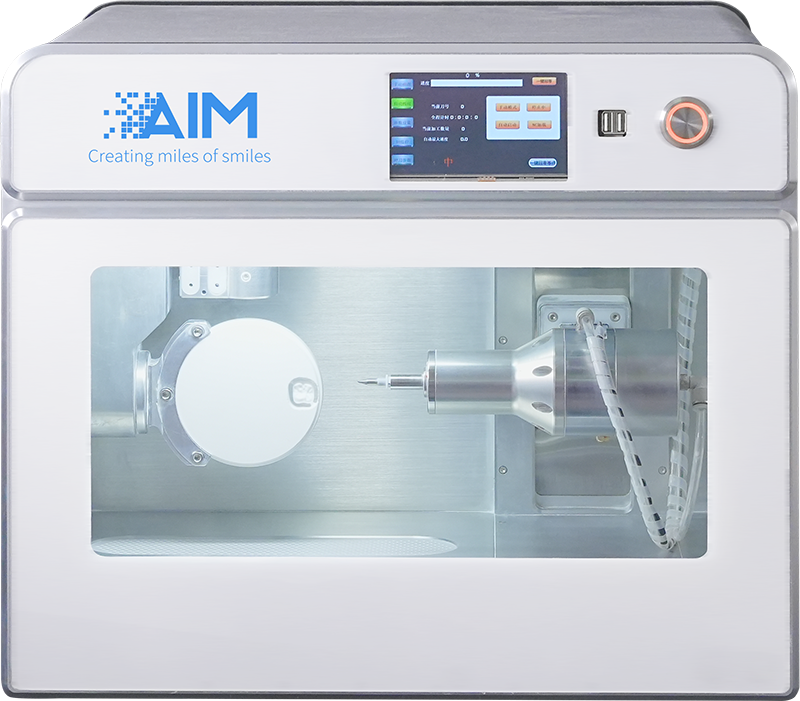

AIM-5Z 5-axis Grinder

- High-definition touch control, simple UI

- Easy switching betweenmultiple languages

Control System

Seamless connection between the built-in computer and the motion controller

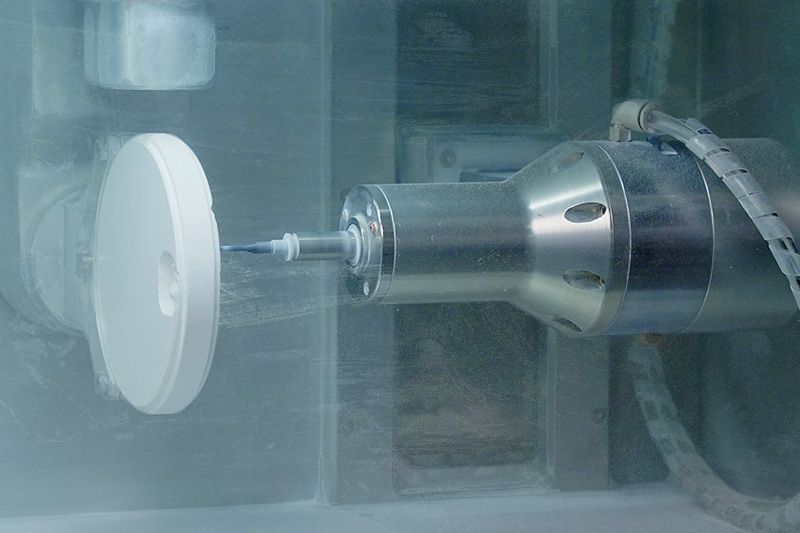

Self-developed electric spindle

- Stable

- Compact

- High rotation speed

Workpiece clamp

- One-click C-type clamp

- Novel C-type clamp to save materials

Equipment structure

Ultra-stable, full aluminum alloy structural frame for aerospace

Work efficiency

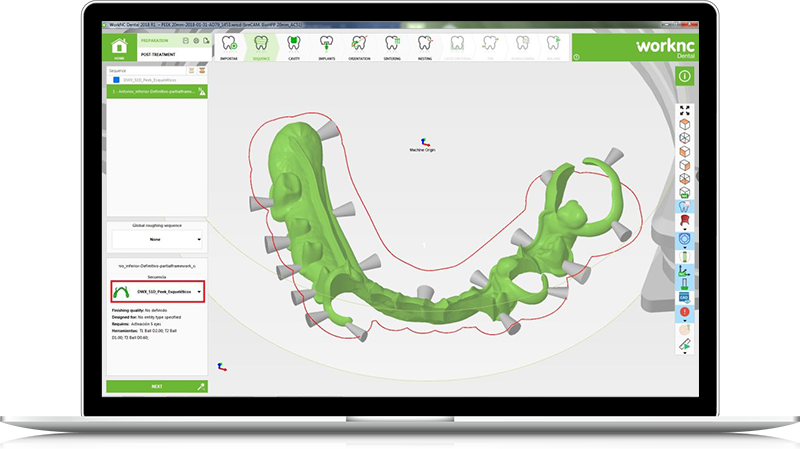

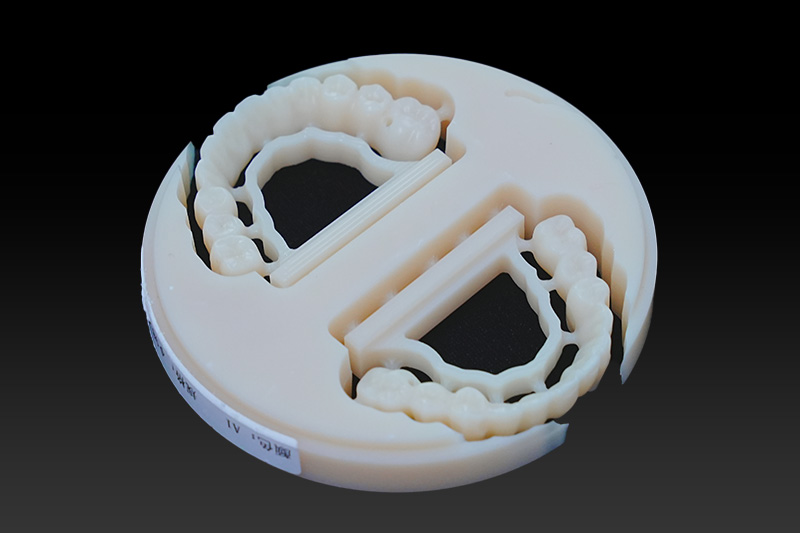

Highly efficient, the cutting time of a single zirconia crown is 11 to 16 minutes (A single computer can be connected to up to 10 AIM machines at the same time)

Cutting data transmission mode

Data can be transmitted through WIFI, network cable, and USB flash drive, which is convenient and fast.

With Worknc、millbox、hyperdent CAM software and timely online technical support,there is no need to worry about grinding strategies

Tool diameter: 0.5 mm

Tool diameter: 1 mm

Tool diameter: 2 mm

AIM-5Z 5-axis Grinder

Name

470*500*465 mm

Dimensions

~50 kg

Weight

220 V, 50/60 Hz

Power voltage

8 tools

Number of tools housed

Automatic tool change

Tools changing mode

Dry processing

Processing method

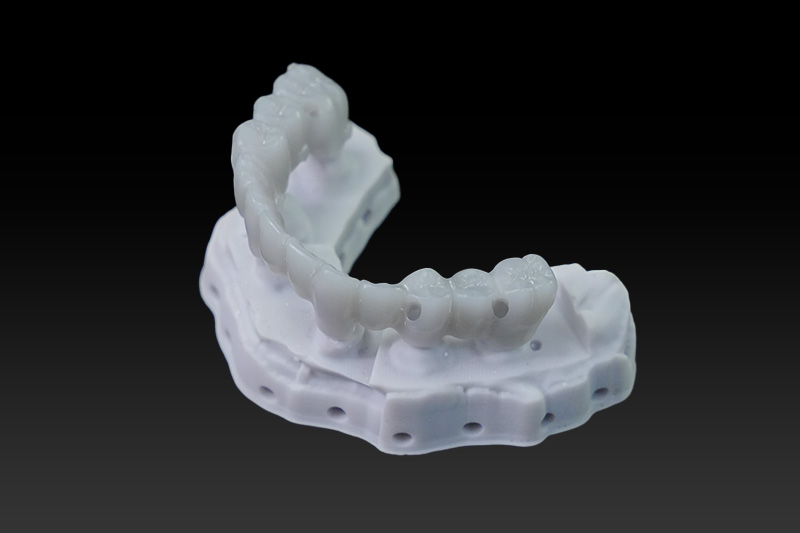

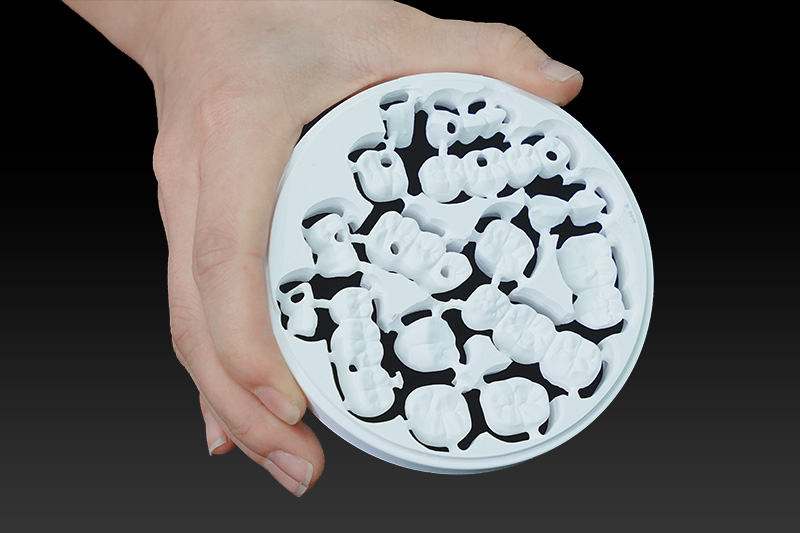

Zirconia, wax block, PEEK (diameter: 98 mm, thickness: 10~25 mm)

Processing materials

Inner crown, full crown, bridge

Processing type

20~60℃

Operating temperature

Noise during operation ~50 dB

Noise

150*105*115 (mm)

A: +10°/-135°

B:0~360°

X.Y.Z.A.B fully closed loop motor; +preloaded ball screw

X*Y*Z Travel range

0.02 mm

Relocation precision

≤1.0 KW (Whole machine)

Power

350 W

Spindle power

10000~60000 r/min

Spindle rotation speed