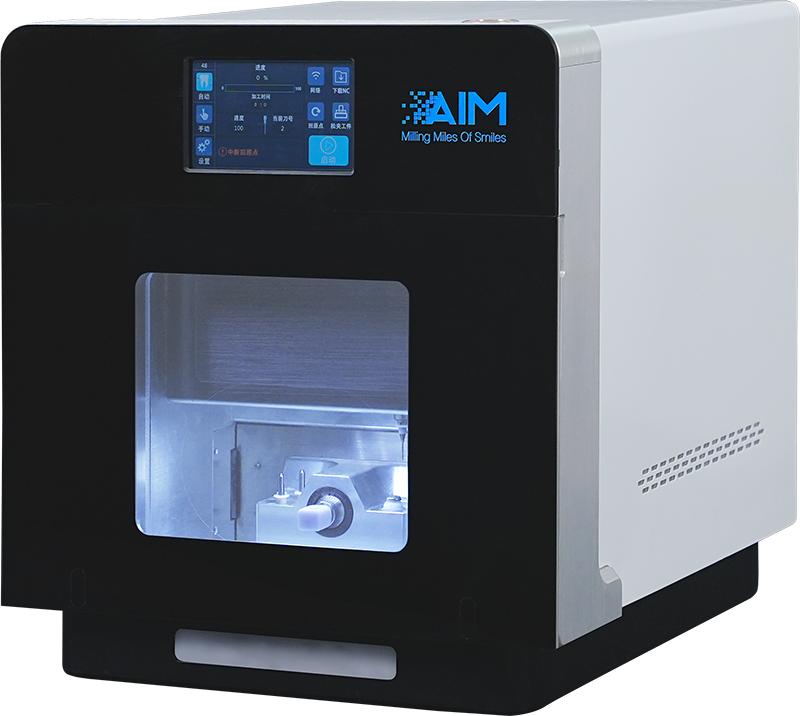

AIM-4Z 4-axis Grinder

High efficiency, simple operation, easy to learn and use. It can serve as an economical entry-level model and can also expand the processing systems of laboratories and machining centers.

High Integration

The equipment integrates a high-precision, high-quality tool setter, with a repeatability of 2μm.

Self-developed Electric Spindle

- Stable

- Compact

- High-speed

Cost-effectiveness

No need for coolant, low usage cost.

Equipment Structure

Ultra-stable all-aluminum aviation frame structure.

Tool Clamping

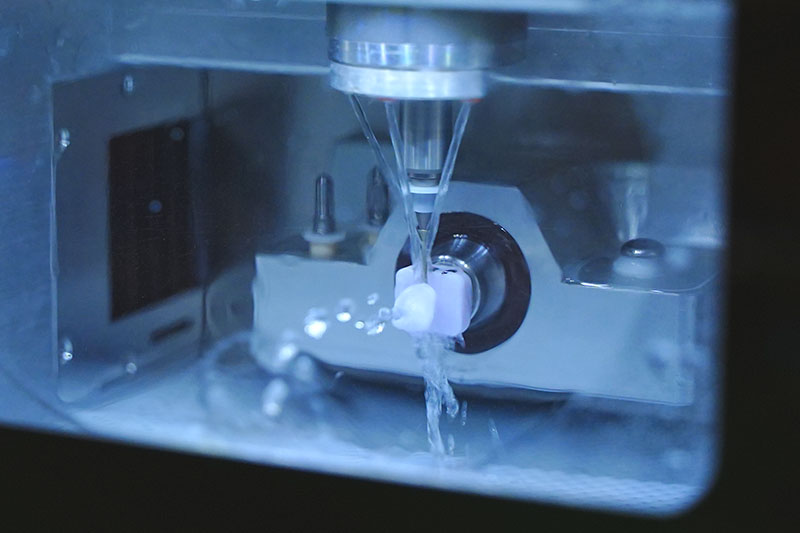

- Patented design for one-key clamping with a new 3-position fixture, capable of simultaneous cutting of 3 ceramic blocks.

- Patented design for one-key pneumatic clamping fixture with detachable tool magazine, facilitating tool replacement.

Cutting Data Transmission Method

Can be transmitted via wifi, Ethernet cable, or USB flash drive, for convenient and fast transfer.

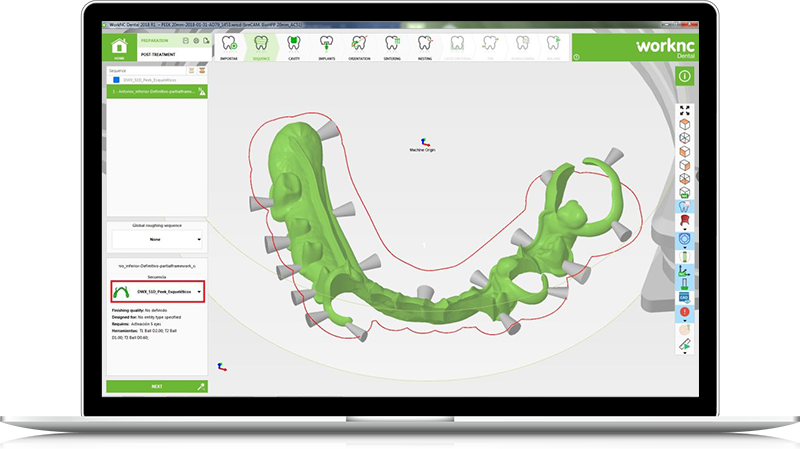

With Worknc、millbox、hyperdent CAM software and timely online technical support,there is no need to worry about grinding strategies

Tool diameter: 0.5 mm

Tool diameter: 1 mm

Tool diameter: 2 mm

AIM-4Z 4-axis Grinder

Name

370*466*370 mm

External dimensions

~47 kg

Weight

220 V, 50/60 Hz

Power voltage

3 tools

Number of tools housed

Pneumatically or electrically automatic tool change

Tools changing mode

Wet

Processing method

Feldspar-based glass ceramics; lithium-based ceramics; hybrid materials; PMMA, personalized abutments

Applicable materials

Inlays, veneers, crowns, full crowns, and open crowns

Processing type

20~40℃

Operating temperature

Noise during operation ~50 dB

Noise

50*50*45 (mm)X.Y.Z.A fully closed-loop drive system;Preloaded ball screw

X*Y*Z Travel range

0.01 mm

Relocation precision

≤1.0 KW (whole machine)

Power

500 W

Spindle power