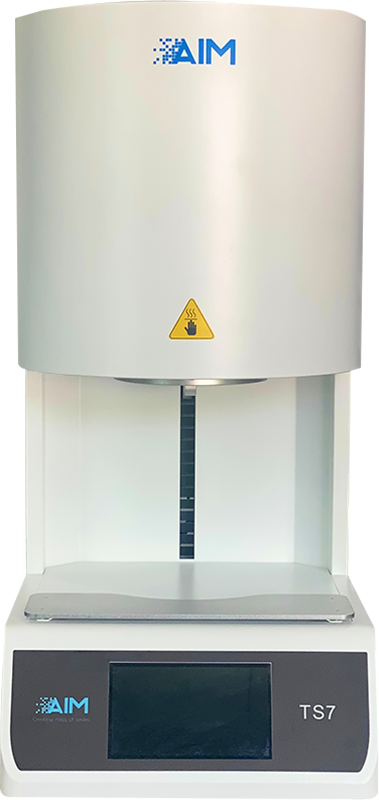

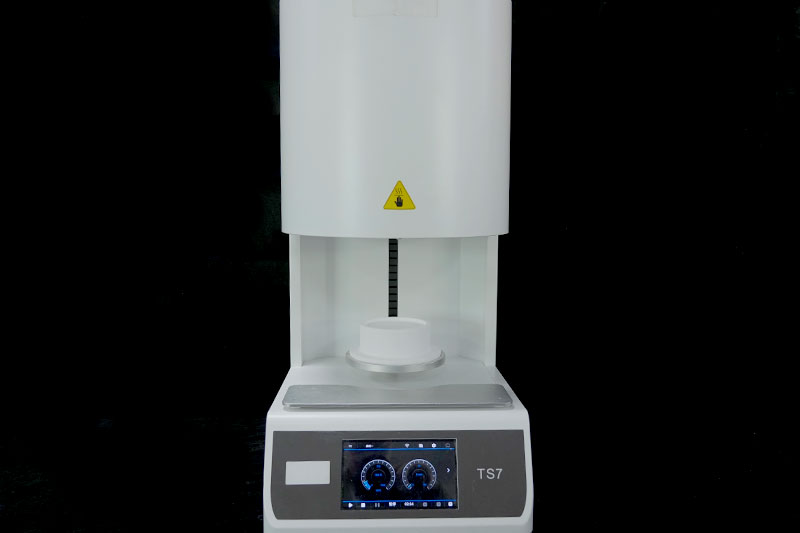

AIM-TS7 zirkoniumoksidin sintrausuuni

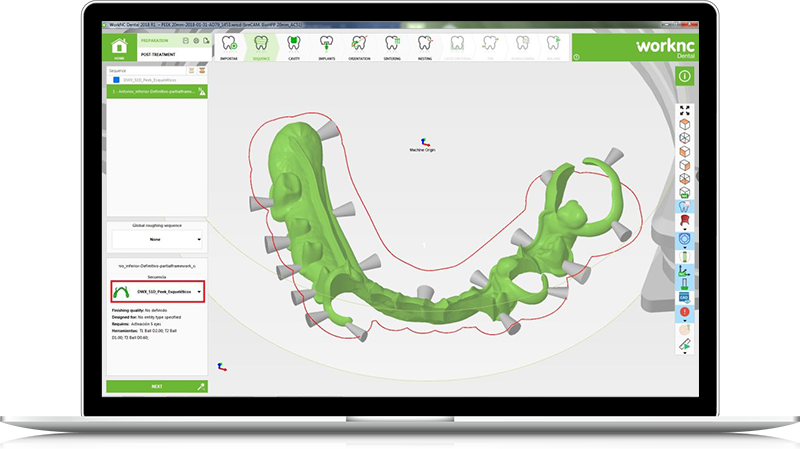

Worknc-, myllylaatikon, hyperdent-CAM-ohjelmiston ja oikea-aikaisen teknisen online-tuen ansiosta sinun ei tarvitse huolehtia jauhatusstrategioista

AIM-TS7 zirkoniumoksidin sintrausuuni

Nimi

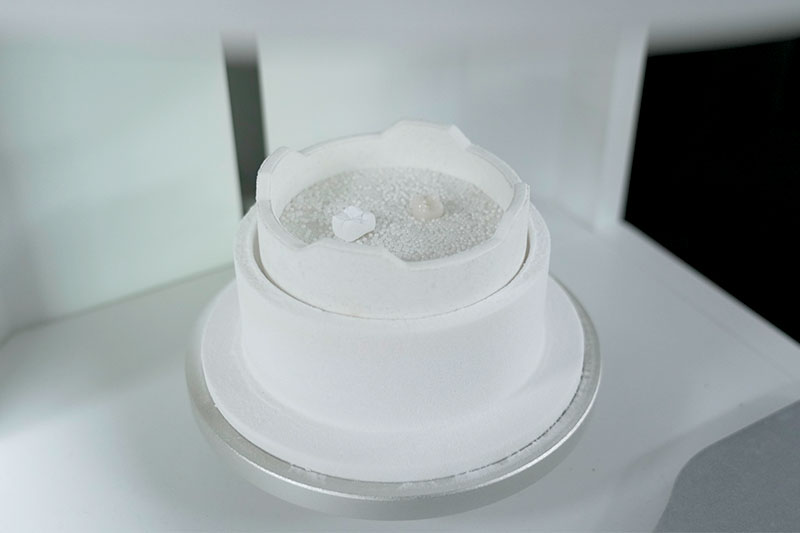

100×120 mm 70×80 mm

Lämmitysvyöhyke

Älykäs PID-monivaiheinen ohjelmoitu lämpötilan säätö

Ohjaustila

±1 ℃

Lämpötilan säädön tarkkuus

20 käyrää, useita aika-lämpötilakäyriä voidaan asettaa haluamallasi tavalla

Lämpötilakäyrä

Digitaalinäyttö

Virran/jännitteen valvonta

Kyllä

Ylikuumenemisen hälytys

>30 kg

Paino

Tyypin B termoelementti

Lämpötilan mittaus alkuaine

220V 50Hz~60Hz 1.5KW 2.5KW

Virtalähde

Hissin tyyppi

Uunikammion tila

Android + Älykäs PID-ohjausjärjestelmä

Ohjauslaite

Tuotu kuitu

Uunikammion materiaali

1600 °C (Mitsubishi)

Äärimmäiset lämpötilat

≤1550 ℃

Käyttölämpötila

≤60 °C (suositus: 10 °C/min)

Lämmitysnopeus

Yksi lämpötilavyöhyke

Lämmityksen lämpötilavyöhyke

377×1500 mm

Uuniputken mitat