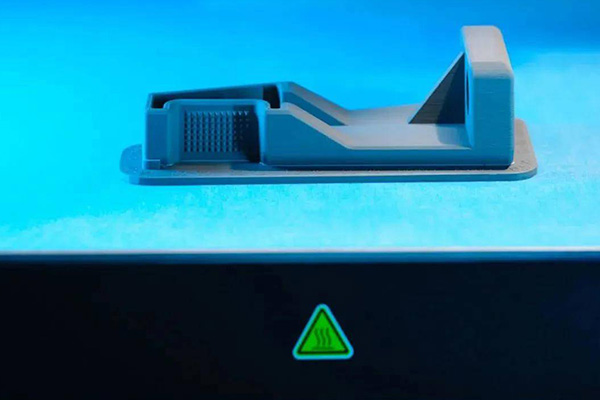

3D printing is a highly innovative rapid prototyping technology. Based on digital model files, it transforms virtual digital models into three-dimensional entities through layered manufacturing and layer-by-layer stacking. This technology breaks through many limitations of traditional manufacturing processes, demonstrates unique advantages and potential, brings significant changes to multiple fields, and plays an important role in the journey of building a manufacturing powerhouse.

The materials used in 3D printing are extremely diverse. 3D printing technology can be compatible with various materials such as engineering plastics, photosensitive resins, metal powders, and ceramic materials. It even has the ability to fuse different raw materials together to achieve composite printing. For example, in the medical field, different materials can be combined to print implants with specific properties. The diversity of materials enables 3D printing to meet the needs of different industries and application scenarios, providing a broad space for the innovative development of the manufacturing industry.

Traditional manufacturing technologies are limited by tools, resulting in a limited range of product shapes. However, 3D printing technology decomposes objects into two-dimensional areas. Theoretically, it can process objects of any shape, offering unlimited design space. The processing accuracy depends on the minimum size of the material particles output by the printer. This advantage is applied in the aerospace field. Some complex components cannot be processed by traditional manufacturing processes, but 3D printing can achieve it easily.

This breakthrough in manufacturing complexity also significantly shortens the product development cycle. 3D printing technology can quickly create concept models, enabling better communication between designers and customers. At the same time, by making functional prototypes and conducting performance tests on them, product design parameters can be improved, greatly reducing the time from product design to production. For example, in the automotive manufacturing industry, using 3D printing technology to make concept car prototypes allows for quick design adjustments and continuous improvements, optimizing products in terms of safety, rationality, and ergonomics. In the medical field, 3D printed customized prosthetics and orthotics can be quickly printed according to patients’ needs, shortening the delivery time and improving patients’ quality of life.

In line with the current trend of environmental protection, 3D printing technology can greatly reduce the generation of waste by-products. Traditional manufacturing methods often involve a large amount of material waste and energy consumption during the production process. In contrast, 3D printing technology achieves precise material utilization and efficient energy management through precise digital control. For example, in traditional metal processing, about 90% of the metal raw materials are discarded in the factory workshop. With the progress of printing materials, “net shape” manufacturing may become a more environmentally friendly processing method.

With the continuous development of technology, 3D printing technology is gradually being applied in various fields. In the aerospace field and rail transit construction, 3D printing technology can be used to produce rocket parts, automotive components, etc. When 3D printing is used to produce small batches of components, it has a cost advantage, can improve productivity, and achieve large-scale and precise production. Moreover, it can be used to manufacture components with complex structures, fully supporting topological optimization, and can integrate multiple components into a whole, ultimately achieving the lightweighting of components.

In the consumer goods field, 3D printing technology gives full play to its customization advantage, endowing products with personalized characteristics and meeting the needs of different groups of people. For example, in the customized shoes field, consumers can obtain data through 3D scanning according to their foot shapes and preferences to customize exclusive footwear products. Home products and electronic product accessories can also achieve personalized customization through 3D printing technology, improving consumer satisfaction.

For artists and cultural relic conservation workers, 3D printing is a powerful tool. Some precious cultural relics are damaged due to factors such as erosion over time. Through 3D scanning and printing technology, the missing parts can be accurately replicated, inheriting cultural heritage. This is also an important manifestation of a manufacturing powerhouse in building cultural soft power.

The most closely watched segmented market of 3D printing is its application in the medical field. 3D printing can assist in customizing dental and orthopedic implants, and even artificial livers using non-living tissue materials such as metals and plastics, providing personalized medical treatment service solutions. It can also manufacture high-precision detection and diagnostic tools for precision medical detection and diagnosis.

The emergence of new materials and new processes continuously stimulates the innovation and upgrading of 3D printing, accelerates the integration of the industrial chain, and improves competitiveness. With its unique principle, wide range of applications, and multi-faceted assistance in building a manufacturing powerhouse, 3D printing technology is gradually becoming an important driving force for the transformation and upgrading of China’s manufacturing industry and its march to the forefront of the world.