On March 11, 2025, the Third Session of the 14th National People’s Congress voted to pass the resolution on the implementation of the 2024 national economic and social development plan and the 2025 national economic and social development plan, and approved the 2025 national economic and social development plan.

The second item of the Outline of the National Economic and Social Development Plan for 2025 clearly states that new quality productivity should be developed in accordance with local conditions, and the modern industrial system should be accelerated to build. The specific contents include promoting the large-scale application of industrial internet, implementing the digital transformation of manufacturing, continuously cultivating and strengthening emerging industries, and deepening the pilot of the integrated development of advanced manufacturing and modern services.

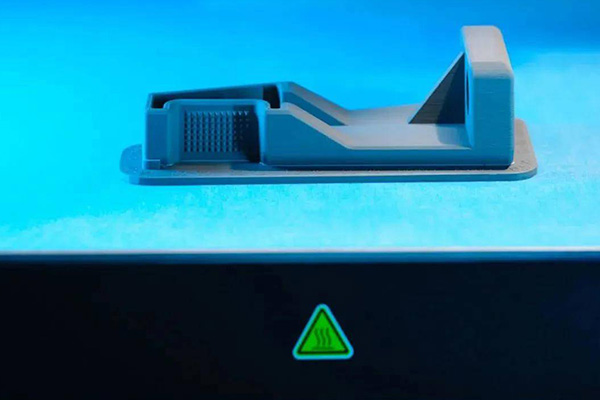

Computer Numerical Control (CNC) technology uses digital information to control the movement of machine tools and the processing process. It is one of the core technologies for the digital transformation of manufacturing and advanced manufacturing. Machine tools processed by CNC technology (machine tools equipped with CNC systems) are called CNC machine tools. The CNC system mainly includes the CNC device, programmable controller, spindle driver, and feed device. The parameters of the relative motion between the tool and the workpiece and the process information (feed rate, spindle speed, spindle forward and reverse rotation, tool change, coolant switch, etc.) are written into a program in a specified format and stored. Then, the CNC system of the machine tool reads it in (or inputs it via communication), decodes it, and makes the machine tool operate and process parts according to the predetermined program.

Numerical control technology and equipment are enabling technologies and the most fundamental equipment for the development of emerging high-tech industries and cutting-edge industries. Modern numerical control machine tools are typical products of mechanical and electrical integration, and they are the foundation and an important component of new-generation production technologies and computer-integrated manufacturing systems. A numerical control machining center is a type of numerical control machine tool equipped with a tool magazine and capable of automatically changing tools, which can perform various processing operations on workpieces within a certain range. Its main features are: after a workpiece is clamped once, the numerical control system controls the machine tool to automatically select and change tools according to different processes. The spindle speed, feed rate, and the relative movement trajectory of the tool to the workpiece, as well as other auxiliary functions, can all be automatically adjusted, continuously performing multi-process operations such as drilling, reaming, tapping, boring, and milling on various surfaces of the workpiece. The machining center can automatically complete multiple processes in a centralized manner, avoiding human operation errors, reducing the time for workpiece clamping, measurement, and machine tool adjustment, as well as the time for workpiece turnover, handling, and storage, significantly improving processing efficiency and accuracy. Therefore, it has good economic benefits. Machining centers can be classified into two major categories based on the spatial position of the spindle: vertical machining centers and horizontal machining centers.

The current transformation and upgrading of the manufacturing industry has led to a growing demand for high-precision, high-efficiency, and intelligent processing. This has pushed CNC technology to constantly break through traditional boundaries. It is not only a demonstration of enhanced technical capabilities but also a precise response to the diverse needs of customers. Besides processing accuracy, technological innovation also lies in the construction of intelligent production processes. By introducing advanced numerical control systems, sensor technology, and artificial intelligence algorithms, CNC processing has achieved full-chain intelligent control from design to production, significantly improving production efficiency and product quality. At the same time, with the increasing diversification of downstream customer demands, customized production has become a new trend in the industry. Processing enterprises must have the ability to respond quickly and achieve personalized customization of products through modular design, flexible production lines, and other means to meet the specific needs of different fields/industries. Moreover, the CNC processing industry has made significant contributions to sustainable green manufacturing technologies. In the face of environmental protection pressure and resource constraints, green technologies such as dry cutting, low-temperature cutting, and minimal/no cutting fluid processing have been widely applied, effectively reducing environmental pollution and resource consumption during processing.

Numerical control technology has developed along with information technology, microelectronics technology, automation technology and detection technology. Its development trend is high speed, high precision, multi-functional integration and intelligence. The level of numerical control technology is related to the comprehensive national strength, especially in the field of key technologies and equipment of “high-end, precise and sophisticated” numerical control. At present, numerical control technology is widely adopted in industries such as information, biology, automobiles, and electronics in various countries around the world to enhance manufacturing capabilities and levels, and improve market adaptability and competitiveness. Its application mainly covers many industries such as automobile manufacturing, aerospace equipment manufacturing, shipbuilding, mold manufacturing, power equipment manufacturing, metallurgical equipment manufacturing and communication equipment manufacturing. Therefore, vigorously developing advanced manufacturing technology centered on numerical control technology has become an important way for countries around the world to accelerate economic development, improve comprehensive national strength and national status.

The Outline of the 14th Five-Year Plan of China points out that to promote the optimization and upgrading of the manufacturing industry, it is necessary to cultivate advanced manufacturing clusters, foster leading and pillar industries, and promote the integrated, clustered and ecological development of strategic emerging industries. The added value of strategic emerging industries should account for more than 17% of the GDP. Advanced industrial equipment such as automobiles, integrated circuits, and robots all use CNC machine tools for precise supporting production. With the continuous enrichment of advanced manufacturing industry types in China, the demand for the CNC machine tool industry is constantly increasing.